Advanced Surveying & Custom Engineering Solutions

Precision Solutions for Industrial Applications

We provide finished product surveys and clash detection analysis for a range of industrial applications, from power plants to oil rigs. Using point cloud data as a basis, we can provide a customised product to suit your specific needs. Whether it’s BIM development, mid-size or powerful industrial platforms such as CAD Worx, PDMS/E3D, SP3D, our team will work with you to provide a solution to fit your requirements.

One of our key expertise areas is industrial 3D laser scanning. We work with such projects as refineries, oil production, steel mills, chemical plants, waste management and water treatment facilities. Our workflows, both in the field and in post-processing, ensures that scan alignment results are within acceptable limits. On demand we provide scan registration reports clearly demonstrating our work’s quality.

Using our equipment and techniques we set the coordinate system to be used for design. We also able to verify construction after the installation.

Majority of our customers use point clouds as a reference in their design work. However, for those customers who are not familiar with point clouds, we offer cloud to 3D CAD model conversion. We support our clients during the design phase, if requested we can model the optimum position for new or replaced items such as pipes, equipment, structural members, etc. Upon completion of the task the client receives a 3D CAD model for review and approval.

Required deliverables for construction (f.i. ISO drawings with MTO) can be produced directly from 3D CAD model seamless with materials’ procurement and following site assembly. This leaves no room for design error, while saving on-site time and potential excess material costs.

Property Development: Complete building measurement service can be achieved with high accuracy and within short time, drastically reducing the amount of site visits required. Full set of 3D and 2D deliverables can be developed based on available point cloud information.

We offer a range of surveying and 3D modelling services for architectural development. As the use of point cloud data becomes more common in the property development market, more architects and engineers are considering the point cloud as the base source of information on the property.

We scan and provide the registered point cloud in the format of your choice. The production of architectural documentation is often the next step. From the point cloud data, followed by a 3D CAD modelling, 2D floor plans, sections and elevations can be created and tailored specifically to the customer’s requirements.

Drone services

Benefits of Using 3D Laser

Scanning:

ACCURACY

High precision laser scanning using the latest hardware

COMPLEXITY

Full capture of geometry for complex and organic shapes.

ACCESS

Data can be captured remotely, safely and non-intrusively.

TIME AND COST

Efficiencies gained by less time on site.

SHARING

Data can be easily shared and reviewed by all stakeholders

MULTIPLE PRODUCTS

Single scan datasets can be utilised to create a variety individual products.

Advanced 3D Modeling &

Laser Scanning

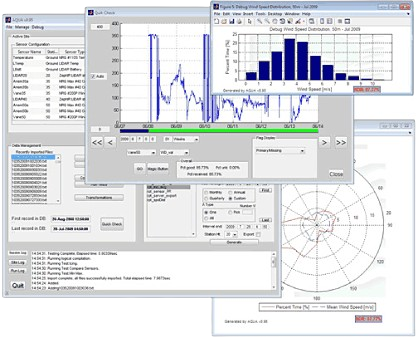

PDMS allows the creation of detailed 3D models of process plants, including equipment, piping, structural elements, and instrumentation.

3D laser scanning really shines when used in historical environments.

The ability to accurately and quickly capture complex and irregular objects remotely has clear advantages over traditional survey methods.

When combined with photographic images, a comprehensive baseline data set can be obtained.

Once this baseline is collected, it can be revised over time as funds or needs dictate the need to extract various products, including:

2D results

High-precision plans, sections, facades, and topographic surveys that provide detailed documentation and accurate spatial representation for design, analysis, and construction planning.

3D Models

Fully developed 3D models available in DWG, DGN, or Revit formats, enabling seamless integration with design and engineering software for enhanced project visualization and coordination.

RGB point clouds (color)

High-resolution, colorized 3D point clouds that enhance visualization and analysis of scanned environments.

Orthoimages

Geometrically corrected images that provide accurate, to-scale representations of scanned areas for precise measurements and documentation.

Mesh Models

Digitally refined 3D mesh models combining scanned data with high-resolution imagery, making them suitable for realistic visualizations, simulations, and even 3D printing applications.

Animations and spans

Dynamic visualizations and walkthroughs that offer an immersive view of 3D models, ideal for presentations and project planning.

Precision Scanning

Reverse Engineering

Reverse engineering made possible with our equipment and techniques. We ensure accurate geometric data collection, material and surface analysis, with creation of accurate 3D CAD models and 2D documentation. Once scanned, your valuable property is available for all design activities.

Reverse engineering is the process of recreation of procedures and technical documentation for and existing object. This necessity is usually present when there is a little or no information at all available, except the initial object itself.

3D laser scanning in reverse engineering is the most effective way to create an exact digital equivalent of a scanned item into form of point cloud data. Modern 3D laser scanners are capable of capturing all information on object’s geometry with an accuracy of 2mm (terrestrial scanners) and 0.5mm (handheld devices).

The resulting 3D geometry of the object, first of all, is the basis for creating a parametric 3D CAD model, which is necessary for further analysis, re-design or replication.

Thanks to modern technologies we may run a few different fit-in scenario with replicated or re-designed parts, aligning parts’ 3D model with point cloud data in one space, before starting the manufacturing process.

Having the complete picture, we can see and correct possible design flaws, optimising the overall design and materials selected.

01

Registered Point Сloud

02

360 Panoramic Tours

Panoramic Images can be supplied referenced to a sitemap allowing the user to navigate around the site in 3D-like environment.

03

3D CAD Modelling

04

2D CAD Documentation

05

3D Virtual Reality

We can digitize a building or a room to provide immersive real-3D experience for our clients. This game-like environment cannot be developed otherwise with standard 360-walkthroughs only.

08

Construction Progress Control

We collect and analyze site condition information during our repetitive scans, to develop a dedicated construction progress report. This information serves to our clients as unarguable basis for contractors’ invoices payments.

Thus, having a 3D CAD model of a physical object, we have the ability to reproduce 2D documentation for the original part, create 2D documentation for re-designed part, and even manufacture the required item on CNC machines or 3D printers using 3D CAD model exchange formats.

Always looking to the future

Main components and tools of the system:

360° Camera

Laser scanner

Specialized Software

Our Vision

The process:

01

Field data accumulated through the construction phase of the project is making possible to compare multiple inspection dates at once to locate elements of concern, check track raised comments and see actual work state at the given date.

02

360 camera stream and Laser scan data compared with project 3D model information representing construction progress measurement – AI assisted, manual (by a quantity surveyor) or both for more complex analysis.

03

HSE measures, works quality and other concerns once addressed would never get buried under field data stream.

04

Full control over the construction process with AI-assisted progress reporting is at your service.

05

Full control over the construction process with AI-assisted progress reporting is at your service.

Our Vision

Possible effects of application:

Implementing this application can lead to significant improvements in project management and execution.

By automating various processes and facilitating better communication and coordination among team members, the application offers numerous benefits.

These include cost savings, increased efficiency, and enhanced quality control.